Drag Week Blog 2008

(This blog was originally posted on the FE Forum in September 2008)

Secret Project Revealed / Off to Drag Week 2008, September 6, 2008

First I must take the opportunity to thank the following individuals for their help with my mad, extensive thrash over the past couple of weeks:

- Jerry C (my Y-block pal)

- Joel N (login GTXJoel)

- Steve P (login F570rd)

- BradFORD S

- Steve S

- Jerry V

- Doug S

- Kevin R

Without their help, I wouldn't be making it to Drag Week this year.

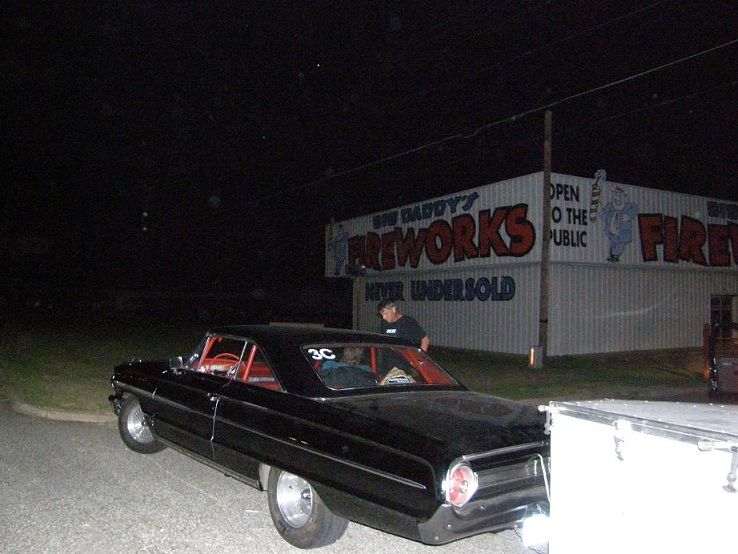

My new car is a 64 Galaxie; I've been keeping it a secret because it came to my attention last year at Drag Week that certain potential competitors were watching the FE Forum for news of what I was bringing. Didn't want to tip anybody off this year.

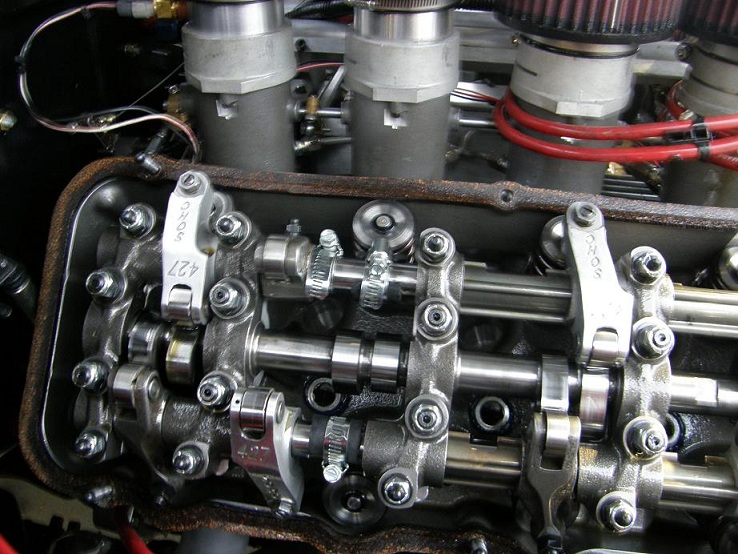

The car has a fiberglass front end, bumpers, and trunk lid, plus a foam back seat to save weight. It is a bench seat, column shift car with a C-4 and Mark Williams components in the 9" rear. It looks remarkably stock on the outside, like somebody's 14 second car. The engine is a 510" SOHC that made 805 HP on my dyno with the EFI converted Hilborn manifold. The thrash I've been going through for the last few weeks has been to get my 585" SOHC ready, and to drop it in the car and take that motor to Drag Week. I had constructed a sheet metal cross ram intake for this engine, and expected to get over 900 HP from it. Here's a couple of photos of the intake, and the completed engine on the dyno this morning:

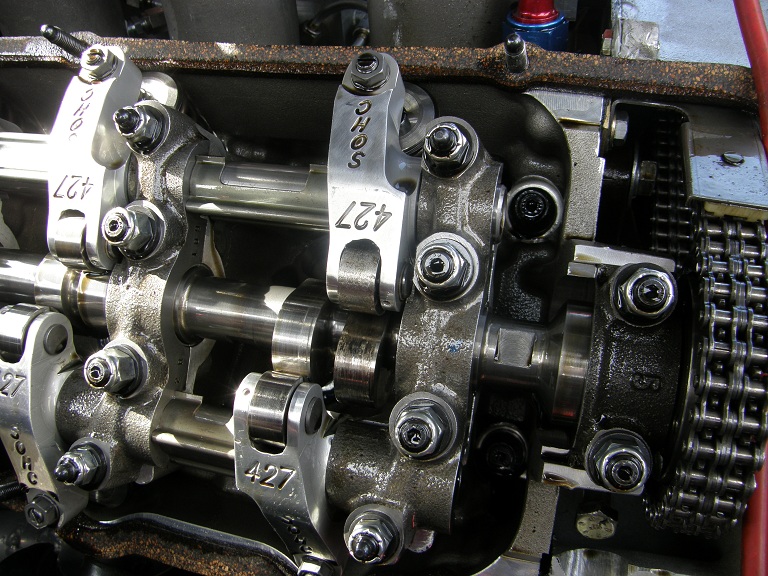

Unfortunately, it was just not to be; I was bitten today by a failure of my dyno equipment, so rather than dynoing the motor this morning, stuffing it in the car this afternoon, and driving south tonight, instead I was fixing the 510" engine from a valvetrain failure that happened two weeks ago, and caused by a Dove rocker arm:

The needle bearing on this rocker is completely destroyed, and put bearing shrapnel all over the left side head under the valve cover. I think I got it all, but there is some possibility that some is still floating around in the motor, and could cause a problem later. I had to replace the left cam because the lobe on the failed rocker was galled. Took most of the afternoon and early evening after we went to "Plan B" to get the car ready for Drag Week.

I'm going in cold this year, because the car has never been to the track, and I still have EFI tuning to do. However, I have about 300 miles on the car with this engine in it, and it has been very reliable and driveable, so I'm hoping that we can tackle the event with no trouble. Joel and I have the car loaded up and are just now leaving. More either tomorrow night or Monday - Jay

Drag Week Test and Tune, Beech Bend Raceway, September 8, 2008

Joel and I rolled into Beech Bend Raceway this morning at 8:00 to start Drag Week, and I was immediately struck by the fact that we were only the third car there. Last year at 8:00 there were probably already 25 cars in front of us at Cordova. I'd heard rumors that the car count was down this year, and sure enough that turned out to be the case; around 3:00 the people at Hot Rod told me that only about 75 cars had signed up for the event, and registration had just ended. So, it looks like a smaller field this year.

After getting our event credentials, Joel and I parked the trailer and unloaded the car. I went about the business of putting on the injector stacks, and I have to admit that although the car can no longer be considered any kind of a sleeper, the stacks look pretty cool:

>

By the way, a quick note on curved stacks per the other post. Bottom line is that with the mandrel bent aluminum tubing available, curved tubes would not fit under the hood. At the front of the intake there is only about 4" of clearance to the hood, and with 2.5" ID aluminum tubes, a tight enough radius is not available. Poking the stacks through the hood was the only option.

After we had the tires on the car and the exhaust system off, we started a check of a few items that would be required by tech, such as lights, turn signals, and horn. To my dismay, my horn wouldn't work. It had worked fine when the car was loaded onto the trailer, so I didn't understand what the problem could be. I spent the better part of the hour chasing this down, and concluded that the steering column of the car was not well grounded. In fact, if you turned the wheel and watched the resistance to ground on my DVOM as it turned, it went from short to open and back again. As it turned out, the horn would not work with the steering wheel in certain positions, and it seemed to work a little better when you were pulling on the wheel. But at least I knew now how to get it to honk and get it through tech.

I started the car to warm it up, and then another problem that I had noticed a couple of weeks ago popped up. This had to do with my Stewart Warner Tach/shift light, which is a digital tach with a shift light built in. It actually looks more like a shift light, but in the middle of the dial reads out the engine speed. In any case, a few weeks ago I'd noticed that it would stop working, seemingly intermittently, and I didn't know why. I had no time before Drag Week to solve this problem, being busy working on the other motor, but as a hedge against this problem I'd purchased a cheap shift light from Summit, and had it packed with my spare equipment. After warming the car up for five minutes, the Stewart Warner shift light quit working, and I knew I couldn't go down the track without a shift light. So, I decided to wire the cheap Summit shift light in parallel with the Stewart Warner unit, to try to determine if the S-W light was defective.

This ate another 45 minutes of time, but when I finally fired the car, the same thing happened; after 5 minutes, the S-W tach quit working. I had set both shift lights to turn on at 3500 RPM, so I revved the engine, and sure enough the cheap light worked, but the S-W light didn't. More brand new, defective equipment! At least I'd found the problem, though.

I spent another few minutes taking out the S-W tach and rearranging the wiring, and by that time the track had opened up and cars were making some passes. Finally, at about 11:00 AM I headed for the tech line. It turned out to be the slowest moving tech line of all time, because a lot of people were registering for the event and getting their cars teched at the same time, causing some delays. Nevertheless, we waited in line and I got to speak with some of my old Drag Week friends. Rob Kinnan from Hot Rod came up and we had a nice chat; he really liked the car and was anxious to see it run. We waited until after noon before we got through to the tech area. Keith Turk was there doing the tech stuff, and he really like the car also. It seems to draw a crowd whenever I pop the hood. Go figure LOL!

At tech, I noticed a vehicle scale right next to the tech station, so after returning to the pits I bolted in the roll cage side bars, threw all my SFI clothes in the car, and returned to weigh it. I was hoping for 3700 pounds with me in the car and the fuel tank empty, and was extremely disappointed to see that the car weighed 3935 with a half tank of fuel! Either the engine and trans is a lot heavier than I figured, or I've added extra weight to the car without knowing it, or maybe my circle track scales aren't accurate. Not sure at this point, and it did dawn on me that I hadn't figured items like my 25 feet of #10 fuel line, the vacuum pump, the electric fans, and the trans cooler into my weight calculations. But in any case, the car is quite a bit heavier than I thought it would be, and running in the nines now seemed a little bit distant.

At this point, there was nothing left to do except go down the track. To start with, I set the shift light at 6500 to make a fairly easy pass, and I planned to foot brake the car on the launch. However, the foot braking would be a little tough because I didn't have a tach to watch during this process. I also set up my laptop in the passenger seat and buckled it in, to let my FAST EFI system log the run. Joel got this photo just as I came out of the burnout box:

The burnout was fine, and I was conservative on the launch, waiting for a bog or some other problem, but nothing out of the ordinary happened on the launch. The car ran nice and straight, but didn't feel particularly fast to me. At the end of the track I let off the gas and applied the brakes, but the engine speed didn't drop all the way back. I missed the first turn off as I realized that the injector throttles had stuck open, so I killed the ignition and coasted around the curve at the end of the track to the return road, and pulled off. A look under the hood revealed the problem; my custom linkage for the EFI system was moving around, being held in place only by a single bolt. It had cocked a little when I gave it full throttle during the pass, and bound up before closing completely. I straighted the linkage out, and went up to get my time slip. The car had gone 10.46 @ 131 MPH, with a miserable 1.63 sixty foot time. I'll admit I was kind of disappointed with this, but in retrospect with the easy leave and the early shift points, I guess it wasn't too bad.

Back in the pits Joel and I tried to figure out how to improve the throttle linkage. We settled on a plan of drilling a second hole through the linkage bracket and into the intake manifold, and then putting a roll pin through the hole to fix the bracket into position. Unfortunately, we didn't have the parts we needed for the fix, so Joel took off in the truck to pick up a long drill bit, a couple of roll pins, and some other items we thought we could use. I took the bracket off the car, and was hanging around when Christopher Campbell from Hot Rod came up. He said he wanted to ride along in the car for a while sometime in the next couple of days, as part of the story for the Drag Week issue. I thought that was pretty cool, and we arranged to plan something for Tuesday or Wednesday. Rob Kinnan came by again a little later, and we had another nice chat.

After Rob left I tried to look at the log data for the run, and was surprised to find that only the first 20 seconds of the log had been recorded. So I got the data for running up the lanes, but the logging shut off before the burnout or the pass. Later this evening I figured out that when I'd upgraded the software last week, it had reset all the data logging parameters, and shut the logging off after 20 seconds. Just more bugs to work out, but thankfully that was an easy one, so next time I should get a decent log on the pass.

Finally Joel returned with the parts, and we made the modification to the intake, but by that time the track was closing for the day, so the only run we got in the test and tune was the first one. After fixing the car, Joel and I loaded it back in the trailer and went back to our hotel.

We had dinner at a local restaurant and formulated a plan for Tuesday. I was concerned about the valvetrain in the engine, and wanted to check the valve lash, so we agreed to do that in the trailer before we went to bed. Since we'd be shooting real bullets on Tuesday, I was going to set up the shift light for 7500 RPM from the start, and try a much harder foot brake launch next time. Also we decided to stop at the O'Reillys on the way back to the hotel and pick up a cheap tach, so I could at least see what the engine was doing at the line. Finally we had a few more minor items to take care of on the car, which we just finished a little while ago.

Tomorrow we have to get into the track at 8:00, unload the car, pack all the stuff in our small trailer, and get the big trailer and Joel's truck in the impound area before the driver's meeting starts at 9:00. I'm hoping to get at least three or four passes in on the car tomorrow, and start working down the ETs. We will see what happens. More tomorrow...

Drag Week Day 1, Beech Bend Raceway, September 9, 2008

This will have to be an abbreviated post, because we were in very late tonight and need an early start tomorrow. Drag Week kicked off this morning with the usual driver's meeting, and everything was pretty much the same as last year. I made three passes today, but had problems on each one, and could only manage a best of 10.52, not even as good as the single pass yesterday. Here's a photo of the burnout on one of the passes:

Despite what I considered to be a poor showing, I was in first place by a wide margin; the field is weaker than last year. Second place is currently held down by a Buick, a beautiful car that ran an 11.09 today I think. Here's a photo:

He had problems today too, and needed to fix some kind of leaking plug on the back of the engine tonight.

After the racing, Joel and I had to pack the trailer full of all the stuff. Here's a shot of the goods before we got started packing:

Believe it or not, we made it fit. Had some trailer problems on the way, and also some driveability problems for the first few miles, but I finally got the EFI system tuned in so that the car ran down the road pretty well. The rest of the trip to Steele, AL went uneventfully, but it was very long, taking nearly 8 hours for the 240 miles. I was hoping we'd drive somewhere close to Chattanooga so I could stop in and see Blair Patrick, but we went nowhere near there. We stopped twice along the way for checkpoints, first at some big statue of a bull, and then at a fireworks store. Pictures:

At the fireworks store, Chris Campbell from Hot Rod joined me in the Galaxie for the ride into Alabama, and we had a nice time talking about cars, mostly Fords. Chris is a Ford guy, and is working on several cars, one of them a 1970 Mach 1 that he would like to put a Boss 429 in. As I recall someone is planning to make, or is already making, shock tower modification kits for a standard Mustang that would make the shock towers look like Boss 429 towers so that engine, or a cammer, would fit. If you know who this is, or know of a link to the company or person that is making these, would you please post it here? I would like to forward it to Chris; he was very interested in it.

Sorry for the abbreviated report; I'll post more detail tomorrow.

Drag Week 2008, Day 2, Alabama International Dragway, September 10 2008

Day 2 of Drag Week was rather eventful, and long. Joel and I started the day thinking that maybe we would be able to get to the hotel fairly early tonight, because the drive from Steele to Montgomery would be only about 150 miles. Unfortunately, that turned out NOT to be the case.

Coming out of the hotel in the morning, parked next to the Galaxie in the lot we found our two Mopar competitors from the BB/NA class. Both cars run mid 11s, and are real sleepers. Here's a photo:

On our way to the track, we stopped at the Wal-Mart across from the hotel and picked up a power inverter to supply power to the laptop during passes at the track. I hoped that this would solve my datalogging problems (yesterday the computer had shut off due to low battery warnings several times, and I'd only gotten one good datalog at the track). We also picked up a few other things, including some work gloves that we had neglected to bring. These turned out to be very useful later in the day.

The drive from the hotel to the track was uneventful and short, and we arrived at Alabama Dragway around 9:15. We immediately began work on getting the car ready to race, and adding in the power inverter to the wiring system. Unfortunately, after installing the inverter, it became apparent that it was underpowered to supply the necessary current to the laptop, and we were stuck with the same old issues in terms of conserving the battery so that we could datalog the EFI data. After working through this for the first hour or so, I was finally ready to go up and make a pass around 11:00.

The first pass was rather embarrassing. I rolled up to the staging lanes, and had to shut the car off because they were cleaning up a spill on the track. This meant that the EFI box was no longer communicating with the computer, and so I had to reset all the data logging parameters while I was sitting there. Finally I got the signal to go, but when I turned the key, the car wouldn't turn over! I thought that maybe I had an ignition switch problem, so to check I raised the hood and turned the motor over with a screwdriver and the starter solenoid. It spun no problem, so I ran off to find Joel, who was in the stands ready to film the pass. He came back to the staging lanes with me, and we started the car with Joel activating the starter solenoid. But as soon as it started it lurched forward, so I shut it off again. It was at this point that I realized I had shut the car off in Drive, and failed to put it in park before trying to start it again. What a bonehead play! Joel laughed at me as I started the car and drove into the burnout box, but after all that I forgot to punch the button to start the data recorder. I ran the pass but mistakenly shifted from first to third, so the result was a 10.65 at around 128. I was not a happy man.

Back in the pits, a big SUV rolled up to the car and some guy with an FE Forum t-shirt got out, and said "You must have mistaken me for someone who gives a damn!" This turned out to be Gopher from the FE Forum, and with him was FalconRed. We had a nice chat in the pits for a while, and then I tried to get my mind back on racing. Another forum lurker who had come out to see the car (and whose name I've already forgotten because I suck when it comes to remembering names) had watched the first pass and said that the tires were spinning on the launch. I decided that I was probably hitting them too hard with the Cal-Tracs in the upper hole, so Joel and I moved the Cal-Tracs to the lower hole, and I went out for another pass.

This time, I got it right, and the car responded with a 10.35 at almost 131 MPH, and the sixty foot time improved by a tenth over what it had been running. The adjustment to the Cal-Tracs seemed to have helped. I felt pretty good about this pass, and was thinking about making another one, but it was already after 1:00 PM and I thought we should get on the road, so we converted the car back to street trim, turned in the time slip and got our directions to the next track. It was only 140 miles, a piece of cake. Joel and I figured to be at the hotel by 5:00, enjoy a leisurely dinner, and relax for the evening.

On the way out of the track, though, we decided to go back to Wal-Mart and buy a bigger inverter for the laptop. The battery was dead again, and I wanted to do some tuning on the road with the car. We picked up the inverter and installed it in the Wal-Mart parking lot, which killed close to an hour. Then we got gas, and Joel suggested we stop at Dairy Queen (he offered to buy), so it turned out to be 3:30 by the time we hit the road. The first 50 miles were uneventful, and the first checkpoint was at the Talladega race track; here's a photo of the Galaxie in front of the big sign:

About 30 miles later, as we were passing through a small Alabama town, the trouble began. As we slowed down to a stop light, we began to hear funny noises from under the hood. Joel noticed it first, and we decided we'd better stop the car and check it out. We pulled into the parking lot of a local grocery store called the Piggly Wiggly, and listened to the engine. The noise appeared to be coming from under the driver's side valve cover. Nothing to do but pull the cover and look.

I had immediately pegged this problem as probably a broken adjuster screw on one of the rockers, because I'd had lots of problems with the RAS rockers before from this issue. But we had to pull the cover to fix it, and the driver's side valve cover on this car is not an easy removal. The master cylinder has to be loosened from its bolts so that it can be moved out of the way for the cover to come off, and also the line lock is installed in the way of the cover, on one of the forward roll cage tubes, and it has to be removed also. This is usually no big deal, but for some reason the line lock bolt was frozen in it's threads, and would spin endlessly without coming out of the tube it was installed in. We worked on this problem for a good 20 minutes before we finally got the bolt out. In the meantime, Jeff McConnell who runs an SBC in a mid '80s Chevrolet came by to help out. Finally, we got the line lock moved out of the way and the cover came off.

My failure theory was immediately blown out of the window when I saw that all eight adjusters were intact. Closer examination revealed a blown rocker arm bearing on the #8 exhaust rocker. I was really surprised to see this; it was the same failure I had seen with a Dove rocker arm before Drag Week started, and after all the dyno pulls and run time I had with my RAS rockers on this engine on the dyno, I didn't think they would fail like this. However, others have told me of their problems with RAS rockers, so I supposed they may be susceptible to this problem as well.

In any case, we were now faced with a disassembly and replacement operation. Fortunately, I have 14 spare Dove rocker arms with me on Drag Week. We took a close look at the cam lobe where the failure occurred, and while it showed some scuffing from the roller, it seemed like it should be usable. Good thing, because I don't have a very good spare cam for the left side of the engine. We tore down the valvetrain on the left side to get a better look at the problem; here's a couple of photos from this phase of the operation. Note the shrapnel pulled by magnet from valvetrain area of the left head:

The gloves we'd purchased at Wal-Mart earlier in the day really saved us while we repaired the engine. The cammer NEVER seems to cool down, and it's very difficult to work on without getting pretty badly burned unless you have some gloves to wear. I estimate we'd have had an extra hour in the repair without them.

We had pulled into the Piggly Wiggly around 5:00 PM, and it was 7:30 before we got out of there and back on our way. Joel and I were listening to the motor very closely, waiting to hear more valvetrain noise, because neither of us really trusted the new rocker on the scuffed cam lobe. However, 75 miles later, at the next checkpoint the engine still sounded pretty good, so it seems like it might live for a while. Here's a photo of checkpoint two on this leg:

Fifteen minutes later we were at the hotel, pulling in around 9:45 or so. What a day! I made a quick call to my darling wife (who is undoubtedly reading this post), to give her a report on the day, and then Joel and I headed out for a late dinner. At dinner we concluded that we had better pull both valve covers at the track tomorrow and check the replacement rocker and damaged lobe, as well as the lash on all the valves, to see if we have any other potential problems in the making. Also we plan to change oil at the track to hopefully drain out any shrapnel that ended up in the pan from today's fiasco, and I'm praying that some of that doesn't work it's way into the oil pump and seize it (like the supercharger shrapnel did in my Mach 1 on the last day of Drag Week last year).

Tomorrow is going to suck because we need to get out of the track early. We have a 350 mile trip from Montgomery Alabama to Memphis Tennessee tomorrow, and I still have to get the maintenance work done on the car and make a decent pass before we can leave. It will probably be another late night, especially if we encounter any more mechanical problems. Wish me luck, guys! More tomorrow night...

Drag Week 2008, Day 3, Montgomery International Raceway, September 11 2008

First let me say thanks for all the kind words from everybody on the forum. Joel and I really appreciate the encouragement!

Also, to answer at least one question, I have two large magnets epoxied to the oil pan of the engine, and I think this is probably helping us contain the shrapel that the engine has been making.

We had an extremely hectic day today, without a lot of good news for the home team. Joel and I got to the track early, and started taking the valve covers off the car to see how the repair from last night had fared, and also to see how the other side looked. Good thing we did that, because we found another RAS rocker that gave up the ghost, the #1 intake. We caught it early, and it didn't put too much shrapnel in the motor, but the roller was seized so it did score the cam lobe a little. The side with the repair from last night looked fine though, so we lashed the valves on that side and spent the first few hours of the morning disassembling the valvetrain on the right side and replacing the bad rocker with another Dove unit.

After that we changed the oil and put the car in race trim, and I was ready to make a pass by about noon. Then, we started the engine; the valve train racket from the right side was unbelievable. WTF? We had just been in there! We tore off the valve cover again, and found a broken adjuster on another RAS rocker. I replaced it and assembled the engine again, but it was still very noisy. Huh? Took off the right valve cover AGAIN, and looked closer, and sure enough we found another problem we had overlooked, a missing lash cap from the #4 intake. How it came off the valve, we had no idea, but I grabbed another lash cap from my spares and we installed it. This time we checked EVERYTHING very thoroughly before re-assembly, and figured we had it. No joy though, the loud noise was still there.

We wondered if the engine was not getting oil for some reason on the right side. We pulled the valve cover for the fourth time, and reinstalled the spark plug tubes and plugs, put some cardboard around the head to keep the oil splash out of the engine compartment, and started the motor. Boy, that was a sight to see, cam spinning, rocker arms moving, and there was oil everywhere! Oiling was clearly not the problem.

We put it together one more time but predictably the noise was still there. It was now 1:30, and I had to make a pass by 2:00 or be disqualified. I decided to make the pass with the engine the way it was, and hope for the best. We warmed up the car and I got into my helmet and jacket, and at 1:45 I went out for my pass. The car made a horrible racket during the burnout, and I was so flustered I hadn't set the line lock properly, so I didn't get a good burnout and the car kind of went crooked during the process. I pulled to the line anyway and launched at 3000 RPM off the brake, and the car spun on the line but seemed to run pretty strong. I had a hard time keeping it straight though, was all over the track and had to let off once, and screwed up yet again on the shift, going directly from first to third; the result was an 11.37 pass. But I had to be happy with this, because it kept me in the lead in my class.

On the return road, I noticed the racket from under the hood was gone! I hadn't a clue why.

Counting my lucky stars that I had actually gotten down the track, Joel and I switched back to street trim and packed the trailer. We were one of the last two or three cars to leave the track, and got out the gate at 3:40. Down the road 30 miles was the first checkpoint, a giant peach, and we got through that uneventfully. However, ten miles farther, the car suddenly started popping like it was going lean; lucky for me there was an exit right there, and I pulled off just as the car died. First thing we did was check the fuel pressure gauge in the engine compartment with the fuel pump on, and sure enough saw zero on the gauge. The pump was running though, so I figured it was probably a clogged fuel filter. I turned the pump on for about 20 seconds, and eventually some fuel pressure would build, but not the 45 psi that the injectors needed.

After briefly talking this over, Joel and I concluded that we didn't really know how the Aeromotive pumps fail, and if we replaced the filter it may still be possible that the problem would still be there. We decided to pull both filters and the pump, which are mounted together at the rear of the car, and replace them with my spares. Naturally, I smelled somewhat of gasoline after this little repair, but 45 minutes later we had fuel pressure in the system, and we were back on our way.

As we rode into Birmingham AL, on a large downhill stretch of highway 65, the valvetrain noise returned with no warning, and boy was it loud! I shut the car off and coasted down to an exit, turned the corner and found an empty parking to park in. We popped the hood and tore into the valve train again.

We found several minor problems. More of the RAS rockers were starting to wear out; we could see the clearances developing in the needle bearings of the rollers. However, on the right side where we were working, there did not appear to be any problem that would explain the noise. We pulled the left valve cover also, and again noted more RAS rockers that were in the process of dying. One had lash that had opened up to .040" or so. We went through and replaced all these questionable rockers with the spare Dove rockers we had brought along, but we were now at the point where the spare Doves that looked good had been exhausted. And none of the RAS rockers had seized the roller bearing, which we had seen in the previous failures.

After two more hours it was 8:30, and we had the engine back together with the minor fixes. But we hadn't found the source of the noise, and sure enough when we started the car, the loud rapping was still there. Convinced at this point that the noise was not valvetrain related, we began to suspect a foreign object in the engine. It might be the missing lash cap, or any number of small parts that we'd been working with at the track. I suppose there is some possibility that someone threw something in the injector stacks, although they had been covered by the air cleaners for the entire morning thrash.

We figured that it got in there somehow at the track, and when I made my pass it had smashed it into the combustion chamber or piston, and it had stuck there for a while before coming loose again near Birmingham, and probably sticking again, but in a place where it would make a bunch of noise when the engine was running. We decided to forego the remainder of our trip to Memphis this evening, because we did not want to risk breaking down in the dark on the freeway to Memphis, so we checked into a local hotel, and went to dinner to talk things over.

The big question was whether to withdraw from the competition, and truthfully I was giving that some serious consideration for a while. Nobody would blame me, I'm sure, with the engine rattling like it was. But after kicking it around a little, it seemed that I really didn't have a lot to lose by trying to make it to the track in the morning. The engine damage was already done and the engine would have to come out of the car anyway. Every mile we made towards Memphis got us that much closer to the truck and trailer at Bowling Green. The car isn't missing, so I don't think we have a valve problem. And if the sound went away once, it might very well go away again, or the foreign object may pass through the engine and out the exhaust.

So, we'll be up at 5:00 AM tomorrow to make a run for Memphis, and try to make a pass at the track. We may not make it far, but I think we have a reasonable chance of getting there. We will see. The bigger question to me is will the rocker arms hold up, and can I somehow nurse the car all the way back to Bowling Green for the last day. We have about 400 miles and 2 passes to go for the NA/BB checkered flag. Banzai!!

Drag Week 2008, Day 4, September 12 2008

I'm out. At 10:00 AM I thought we had a good shot, but at 10:15 I knew it was over.

A few catch-ups from yesterday. Here's a photo of the broken rocker we found at the track on Thursday morning. The roller is seized and it is galling the cam:

After leaving the track yesterday, we drove 30 miles uneventfully and made it to the first checkpoint, a giant peach at a place called Peach Park:

More problems 50 miles after the checkpoint. Here's a shot of the engine apart in the parking lot of a medical building in Birmingham, AL, as we took apart both sides of the motor and carefully inspected each piece. During this operation last night we replaced another five RAS rockers.

This morning Joel and I were up at 5:00, ready to drive to Memphis. For some reason it dawned on me bright and early today exactly what was wrong with the engine. Yesterday during our thrash at the track, we had removed the top rocker shaft on the right side, in order to replace the damaged rocker shown in the second photo above. On each valve stem there is a lash cap. I'm nearly certain that when I pulled the top rocker shaft off the engine in order to replace the #1 rocker, the lash cap from the #4 intake valve stuck to it's rocker arm briefly and then fell into the spark plug hole of #3. I've seen them stick like that, and in our haste to get the engine together at the track, its something that could easily have happened.

This scenario fits with the sequence of events that followed. After re-assembly we started the engine and heard a noise on the right side. We took the valve cover off again, and the foot of the adjuster for the #3 intake valve was broken up. I've never seen that failure before, so it was a little odd. Probably the lash cap wedged between the piston and the valve, and something had to give, in this case the adjuster.

We replaced the adjuster, but did not do a thorough check of the other valvetrain components, believing that we had found the problem. We started the engine again; still noisy on the right side. We took the valve cover off again, and this time saw the missing lash cap on #4 intake. We could not find it in the crevices of the head under the valve cover, and figured it went down the oil return. We replaced the lash cap with another, and started the engine again; still noisy. Probably because the lash cap was still in the cylinder.

I tried out this theory on Joel, and he agreed 100% that this was the likely cause of our problem. He further suggested that during the quarter mile pass at Montgomery, the lash cap probably got mashed into the piston or the head, and stuck there for a while. We drove for 70 miles without incident after that, but the sudden return of the rattle indicated that the lash cap had come loose.

Somehow, it felt better knowing what the problem was. Screw that little lash cap, we were going to Memphis! Back on the road, the car sounded like a diesel with all the rattling, but we pressed on through Birmingham onto Highway 78. We stopped to get gas, and then went back on the highway, but within a mile the rattling sound had changed to a louder, more urgent sound. Joel and I figured we had broken another adjuster on the #3 rockers, so we pulled over into a truck stop to pull the right valve cover and take a look.

When we pulled the cover, we were surprised to find no problems. All the rocker adjusters looked good, as did the rocker arms and rollers. This told us that the lash cap had moved again and was rattling around, or maybe stuck in a different place.

Rather than having this happen on a running cylinder, Joel and I thought it would be safer to kill that cylinder on the drive, so the lash cap didn't get stuck in a valve and bend it or something. So, we pulled the rocker shaft clips on number 3, and moved the rockers over so they were not contacting the valves. Then we took a short length of heater hose on each rocker shaft, and positioned it in place to block the oil hole. We held that hose in place with some hose clamps, and also used another hose clamp to keep one of the rockers away from the cam. Talk about a Mickey Mouse repair, but it seemed to work:

We clipped the electrode on the plug for #3, pulled the fuel injector connector, and taped a rag in place over the spark plug hole for #3 with some duct tape (the spark plug tube wouldn't fit with the rockers out of position). Finally we taped the plug wire on top of the rag to keep it from arcing to the valve cover, and set off again. We had just spent an hour and fifteen minutes on this little fix, and it was now 7:30 and we hadn't gone very far, so the time was starting to catch up with us.

The next 80 miles were smooth sailing. The racket under the hood died down after a few miles, and by the time we'd gone 20 miles, the noise was gone again; we figured the lash cap had re-embedded itself in the piston or head. Even running on 7 cylinders the engine had more than enough power, and we ran down the freeway towards Mississippi at 75 MPH. Everything was sounding good, but after about 70 miles we began to smell some oil from under the hood. We figured it was not a big deal, probably the rag blocking the hole in the valve cover getting soaked, but we decided to stop and check it anyway. Sure enough, that was the problem, but when we went to restart the car, we heard that awful grinding sound indicating that we did not have good engagement between the starter and the flywheel!

What now?? We jacked up the car and took a look. I was able to wiggle the starter freely with my hands, but the bolts were still tight holding the starter to the block. My starter is one of those 360 degree rotatable Powermaster starters, and apparently the two allen bolts that locked the rotating part in place had come loose. We had to pull the starter out of the car and retighten those bolts. After re-installation, the car started fine, and we were on our way again by 9:30. But we'd lost more precious time.

Back on the road, we began to make plans for the track. We had another 150 miles to drive, and a checkpoint to stop at, before we got to the track in Memphis. Joel and I figured that to reverse the fix we had made early this morning, and get the car ready for a pass, would require an hour. The track closed at 2:00 PM, so this gave us about an hour of time to spare. If nothing else went wrong, we would make it.

At 10:15, our plan came apart. The dreaded noise of another failing rocker arm, from the left side of the engine this time, made me pull over on Interstate 78. This time, it turned out to be one of the Dove replacement rockers we had put on that side. Same issue as before, bearing gone, roller seized up, galling the cam.

We were now out of time. The rocker replacement would take at least another hour, and probably more. Further, the rockers had been failing with alarming regularity; every 70 to 100 miles, we seemed to lose one. That meant it was likely that we would have still another rocker failure before we got to Memphis.

I made the difficult decision to hang it up. I called AAA and they sent the flatbed that you saw in the first photo. I'm cooling my heels here in a hotel in Mississippi, while Joel is on the way to pick up the truck and trailer in Bowling Green. He'll drive it back late tonight or tomorrow, pick up me and the car, and home we will go. We will miss the rest of Drag Week.

The car received a lot of attention at the event, and the motor especially was much admired by the Drag Week crowd. The truth, though, is that with the RAS or Dove rockers, it was not a reliable street engine. I'm especially disappointed with the RAS rockers, because I've had such good luck with them on this engine on the dyno. They probably have over 150 dyno pulls on them, and they never showed any sign of wear or problem with the roller or bearing. Obviously, 3000 RPM down the interstate for an hour puts a different load on the rockers than a 15 second dyno pull, and this difference showed up as accelerated wear in the roller bearings.

Thanks again to all you guys for your support on the forum; I really appreciate it. Joel and I worked our butts off again this year, but not finishing leaves a pretty bitter taste. I'll have to solve this rocker arm problem and do better, with the big motor, next year...